Gabaɗaya samfur:

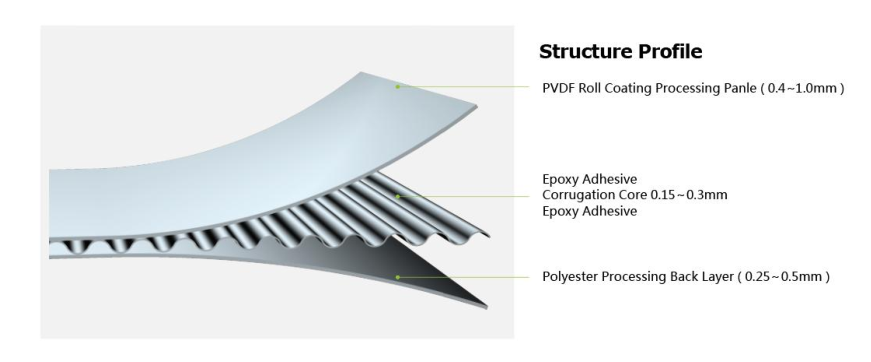

Aluminum Corrugated Composite Panel kuma ana kiransa aluminum corrugated composite panel, ta yin amfani da AL3003H16-H18 aluminum gami abu, tare da fuskar aluminum kauri 0.4-1.Omm, kasa aluminum kauri 0.25-0.5mm, core kauri 0.15-0.3mm.It aka samar a kan ci-gaba atomatik samar da kayan aiki a karkashin sanyi latsa samar da siffa da ERP samar da siffa. layi, ta yin amfani da resin dual tsarin thermosetting manne da fuska da kasa aluminum a cikin baka siffar, ƙara m ƙarfi, mallaka karfe bangarori da kyau manne.make tabbatar m ikon barga da raba guda rayuwa tare da gini.

Aluminum Corrugated Composite Panel aiki na biyu:

> yanke

- Aluminum Corrugated Composite Panel Yanke yakamata yayi amfani da injin yankan na musamman, yanke gwargwadon girman da aka ƙera bayan gyara akan dandamalin lebur.

- Yanke gefen yakamata ya zama mai kyau da tsabta.

> Girma

Muhimmin hanya wajen sarrafa Aluminum Corrugated Composite Panel shine

grooving 0.15-0.2mm a kan kasa aluminum.Processing kwana bayar da shawarar yin

kasa aluminum da corrugated core tare zuwa 91 digiri kwana.

1) Sayen sarrafawa iri ɗaya ne da hoton tsakiya na ƙasa. Yi amfani da gani tare da R5.5 da kusurwa 91

digiri.

2) Don babban tsagi, yi amfani da tsagi a cikin hoto da motsin injina

kayan aiki don inganta ingantaccen samarwa.

Grooving: bisa ga zane zane, mayar da gefen hanyoyin ya kamata yanke

bisa ga hoton hagu.

> Yin gyare-gyare

- Siffata bayan tsagi, gyara samfurin akan wani dandamali mai lebur, lanƙwasa kusurwar digiri 90 tare da matsi mai lanƙwasa bisa ga ginshiƙi ƙira.

- Sashin kusurwar lanƙwasa dole ne ya kasance madaidaiciya (a lura cewa don hana lalacewa a sashin kusurwa, aikin dole ne a sarrafa sama da 10 ° C.

- Lankwasawa tsawo na aƙalla 20 mm sama da gefen ƙira, wannan ɓangaren kusurwa tare da gel silica na iya cimma kyakkyawan sakamako mai hana ruwa da sauran kaddarorin.)

> Girgizar Gindi

- Samfuran sarrafa digiri, yi amfani da farantin karfe uku na yau da kullun.

-Masu sarrafa kayan baka suna kiyaye 100mm suna farawa azaman ma'auni.

- Lokacin mirgina, ba zai iya tsayawa ba.

- Ya kamata kula da shugabanci, gungura dabaran baka da core allo a tsaye shugabanci.

> Sanarwa Don Ƙarfafawa

A) Lankwasawa biyu da yanke bayanan martaba mara daidaituwa

- Cire 0.15-o.2mm daga takarda na waje yayin tsagi.

-Lanƙwasawa ƙwanƙwasa baya saka flange zurfin isa.ba da shawarar saka manne cikin flange a iyakar.

- Grooving bukatar gogaggen mai aiki, ba da shawarar yin amfani da ƙwararrun ƙwararrun masani

- Rashin daidaituwar matsi na injin tsinke yana haifar da lankwasawa sashi mara daidaituwa, ba da shawarar kiyaye karfin sarrafa injina.

B) Bare kayan core daga fuskar fuska

-Lokacin da aka ga dalilin bawon, don Allah a duba yankan gani kafin sarrafa.

-Lokacin da notching, kar a haye grooving tsakiyar layi, in ba haka ba sakamakon bayan lankwasawa ba zai hadu da zane da ake bukata.

Aikace-aikace: